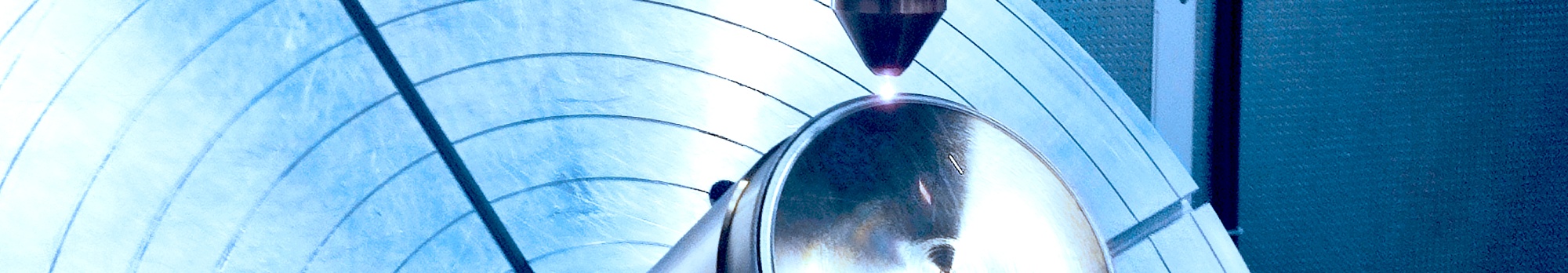

Laser Hardening (LH)

Laser hardening is a method of the surface modification by rapidly heating the treatment zone above the phase transition temperature and then cooling by heat removal into the internal volumes of the material.

Purpose:

- surface strengthening of parts operating at high loads and subject to rapid wear;

- increase of surface resistance to friction, corrosion, wear due to change of chemical and mechanical properties of part surface;

- growing volumetric parts.

Advantages:

- no need to use long-term heating furnaces;

- no deformation;

- complete control of the geometrical parameters of the treated surface zone and the degree of material strengthening;

- automated process control system, which enables to achieve high stability of part hardening parameters;

- the hardening process occurs due to intensive heat removal deep into the metal.

Application:

- mechanical engineering;

- oil and gas;

- chemistry and recycling;

- metallurgy;

- energy.