Competence

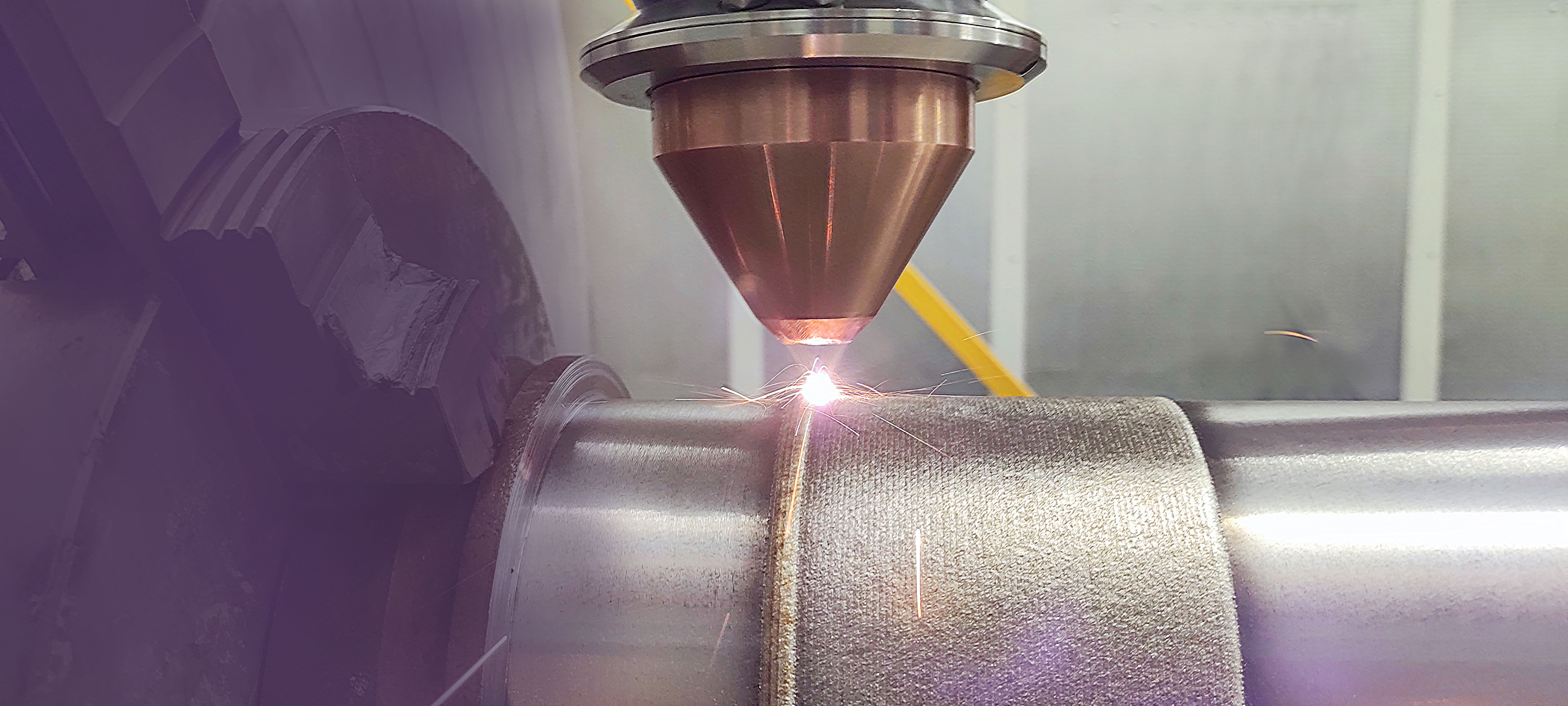

Surface modification

Our methods of gas thermal spraying, laser surfacing, laser hardening, heat treatment allow us to modify the surface properties - increase its hardness, resistance to corrosion and wear, change the friction coefficient, electrical and thermal conductivity, and so on.

Recovery and repair

We use gas thermal spraying, laser cladding and heat treatment technologies to restore the parts surface geometry and increase the working life of worn parts. It is expedient and economically beneficial for many enterprises in various industries.

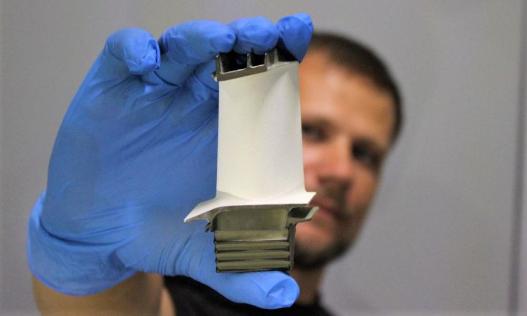

Equipment and complete production

Key focus is to design, develop, produce and commission of coatings equipment, additive production, including mobile complexes, as well as production areas for gas thermal spraying and laser cladding at various industries enterprises.

Reengineering

If you need to replace a worn part that cannot be restored, we are ready to recreate the drawings and make a new part with an increased working life.

Technological Systems for Protective Coatings

We cooperate with enterprises of energy, oil, gas, oil refining, metallurgical, shipbuilding, aircraft building and other industries, providing a wide range of services from R&D to serial coatings or turnkey organization of thermal gas spraying and laser cladding process at the Customer's enterprise.

Targets

Release of competitive products

Creation of domestic production of spraying and surfacing equipment

Maintaining a Leading Position in Surface Engineering

Features

More than 20 years of experience in thermal gas technologies, >100 types of shells

Individual approach to every customer

Design and Technology Bureau

Production of a full technological cycle

Research laboratory

>1000 coating solutions