Engineering, Revers-engineering and Consulting

Coated parts reverse-engineering required if:

Coated parts reverse-engineering required if: - Technical documentation for the part has been lost;

- The part was discontinued;

- Need design optimization;

- It is necessary to develop new equipment for the existing products production or processing;

- Production of parts with coatings in accordance with analogues, for example, according to the import substitution program;

- Recreate parts with coatings that are not recoverable.

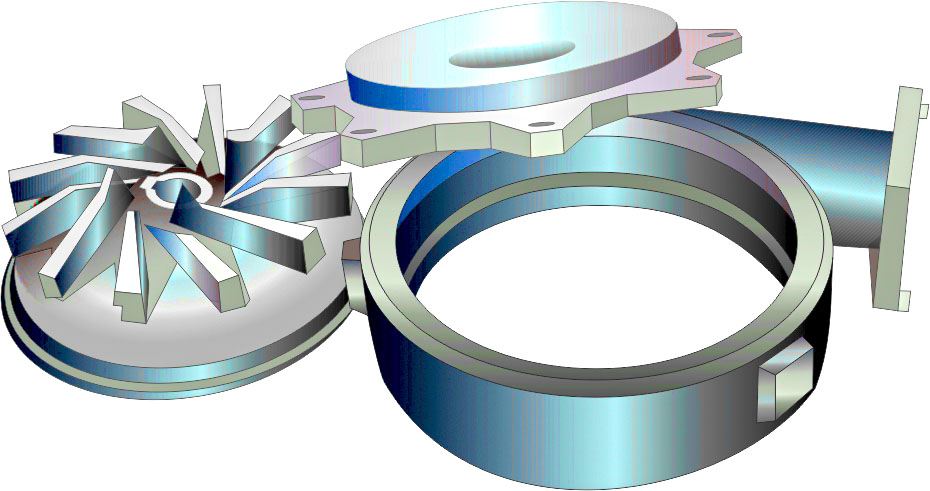

We carry out a full range of work: ·

- Research and development;

- Technology development;

- Drawings reconstruction and other documentation in the interests of organizations operating primarily in the engineering sector of the economy using gas thermal coatings and laser surfacing;

- Production of prototypes, testing

Benefits of reengineering

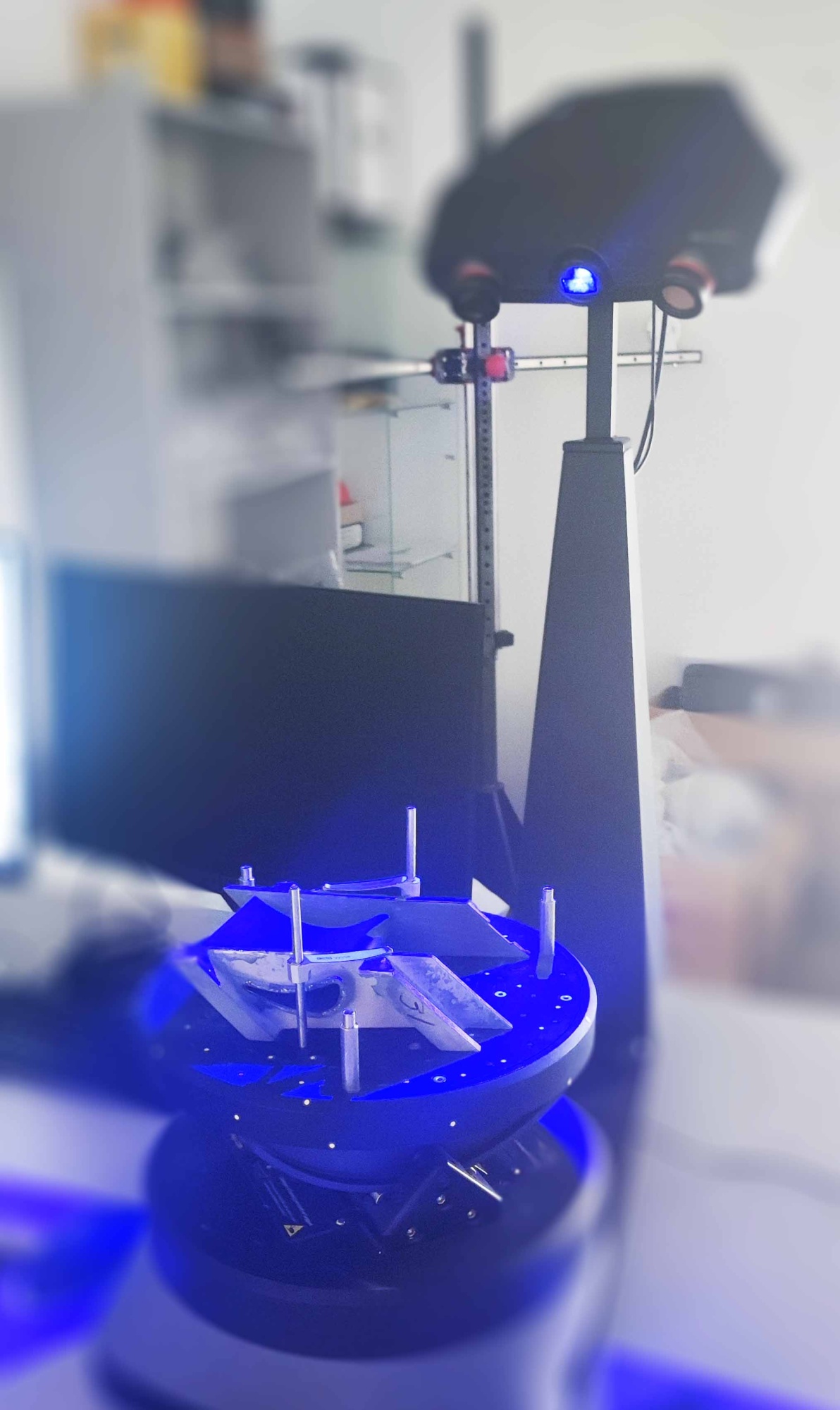

Reverse-engineering can significantly reduce the cost and time of production of products:

1. Time. Our software allows you to speed up the measurement by reducing the time to several hours.

2. Accuracy. Eliminates the possibility of error when dimensioning.

3. Versatility. Allows you to create a model of any shape.

4. Clarity. Control of the prototype at any stage with prompt tracking of changes.

5. Import substitution of coated parts and assemblies, effective replacement of plating and galvanizing.